|

SCARF SWAG:

|

|

Also know as

a Throw Swag, the Scarf Swag is a relatively simple treatment. It

is basically one long piece of fabric which is folded and draped

to form a swag and tails. Standard instructions for mounting this

treatment will have you accordian fold the fabric, drape it over

the holdbacks and pull on the center folds to form the swag shape.

This method is time consuming, frustrating, rarely results in a

neat swag and cannot be touched for cleaning.

This article

will teach you the components of a scarf swag. Once understood,

you will be able to fold a scarf swag into perfect pleats in one

step, pattern a treatment with multiple swags on one continuous

piece of fabric, plan for specific drop lengths on the tails - including

asymmetrical applications, and fold a ready-made scarf swag perfectly.

|

|

|

Note: The pictures used

in the article were taken when I hung ready-made scarves for a client. They

are unlined, and each window has its own full scarf. This was done on-site

so I could not do any formal stitching.

Determining Pattern Dimensions:

Before building your pattern

or cutting the fabric, you must determine the finished dimensions of the treatment:

|

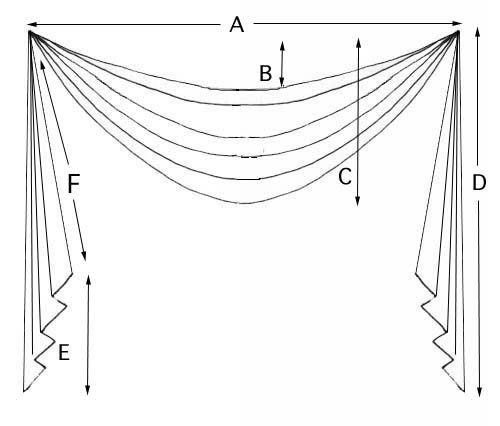

A - Finished face

width of the swag. Measure from the center of each holdback.

B - Cutout drop

on the swag. This is the measure from the top of the treatment

to the bottom of the swag cutout. If the swag is to be designed

with a straight top, your cutout measure would be zero.

C - Finished drop

length of the swag. This is the measure from the top of the treatment

to the bottom of the swag.

D - Finished drop

length of the tails. This is the measure from the top of the treatment

to the bottom of the tails.

E - Slant depth

of the tails. This is the measure of the drop from the inside

line of the tail to the bottom of the tail.

F - Leading edge

of tails.

|

Fullness. Because the

swag is pleated from one long scarf of fabric, it defies some of the basic

rules of fabricating soft swags. The swag portion of this treatment is hung

on the straight of grain and has no curve cut into the bottom line. As a result,

the folds do not hang well and tend to kink. Therefore, you would be wise

to plan on 1.5 - 2 times fullness for most fabrics.

Later, under Scarfswag

Options & Variables, we will discuss how to manipulate fullness, the

dimensions of the slant dept, asymmetrical variations, multiple swags on one

treatment and contrast lining in the tails.

Fabricating

the finished scarf:

Cutting

dimensions:

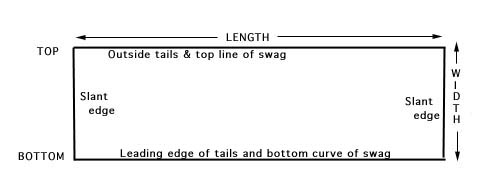

The scarf swag is simply

one long piece of fabric finished to specific dimensions, then pleated into

a swag shape.

Cut length of the fabric:

Sum of both tails 2(D) + Finished width of treatment (A) + Cutout depth

(B) + 2 inches ( seams & ease).

Note:

Computing the finished width (A) + Cutout depth (B) is a simplistic

method for determining the cut length of the swag top. If the fabric

you are working with is stiff or stretchy it could affect the cutout

depth by making it too high or too low. If you wish to obtain an exact

measure, use the fabric itself. Pin the selvage edge of the fabric to

your board in the exact cutout and finished width you desire. Measure

the selvage edge between your pins for a perfect measure. Use this method

to determine the bottom curve width of the swag also.

Cut width of the fabric:

Can be one of three options:

1. Full width of fabric

seamed with full width of lining or finished on four sides with a scant

rolled hem. A standard 54" width of fabric will provide a finished

width of 50+", giving 2.5 - 3 times fullness to a swag 16 - 18"

in depth. Even with very soft fabric, the folds will be crowded and will

kink.

2. Full width of fabric,

folded in half lengthwise and seamed on three sides. Folded edge would

be the bottom line of the finished swag. A standard 54" width of

fabric will provide 25+", giving a 1.5 - 2 times fullness to a swag

12 - 14" in depth.

3. Full width of fabric,

trimmed to desired fullness, depending on finished drop length of swag.

Two widths of fabric can be seamed together lengthwise to increase the

fullness of a longer swag, but care must be taken to make sure the swag

is full enough to hide the shadow of a horizontal seam and the seam is

pleated towards the back of the swag. If trimmed or seamed to a specific

width/fullness, the scarf can then be finished either with a matched lining

or a scant rolled hem on all four sides.

Finishing the scarf:

The scarf can be finished

in one of several ways:

If using a full width

of fabric and the selvage edges are neat and clean, they can be used as

finished edges. Simply sew a scant rolled hem on each of the two ends.

Sew a scant rolled

hem on all four sides. Please note that the tails will show some of the

back of the fabric along the slant edge. If the back of the fabric is

as nice as the front, this will be a satisfactory finish. Otherwise, you

should line the treatment.

Line the entire treatment

with plain lining or a contrast fabric. Simply cut the lining 1/4"

smaller than the face fabric all around to prevent the lining from rolling

to the front of the finished treatment. Sew around on all four sides,

leaving a 6" opening on the top edge. Clip corners, turn and press

flat. Later, under Scarfswag Options

& Variables, we will discuss how to put standard lining in the

body of the swag and contrast lining in the tails.

Trim can be added

to the swag during the finishing process. If unlined, the trim can be

topstiched on the face of the fabric. If lined, the trim can either be

encased in the seam or topstitched on the face of the scarf after it has

been sewn, turned and pressed. Attach trim at the top corner, down the

side, across the bottom and up the other side. You can cut a gentle curve

into the bottom corner for a softer look.

Marking

and Pleating The Swag:

The secret to an easy

scarf swag is drawing the swag shape and pleating it in a perfectly symmetrical

shape.

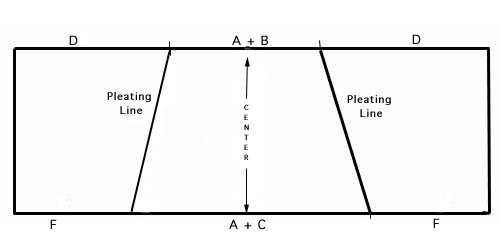

Find the center of your

scarf. At the top of the scarf, mark the points, balanced off the center,

for the top width of the swag. This measure is either the sum of A+B or

the result of pinning the fabric to the board as noted under "Cutting

Dimensions."

At the bottom of the

scarf, mark the points, balanced off the center, for the bottom curve width

of the swag. This measure is either the sum of A+C or the result of pinning

the fabric to the board as noted under "Cutting Dimensions."

Using tailor's chalk

or non-permanent ink, draw two pleating lines, connecting the top of the

swag to the bottom. These will be your pleating lines.

|

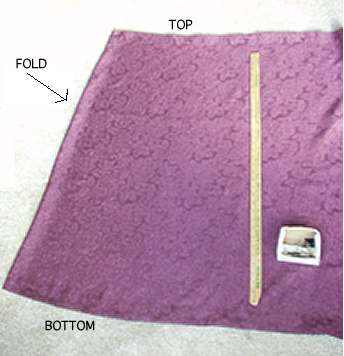

This is a rough

picture. But it shows a scarf folded in half lengthwise on the floor.

The bottom edge looks curved, but it is actually straight.

The ruler shows

the slant line. It points to the measure at the top for the top width

of the swag and the measure at the bottom for the bottom curve of the

swag.

In most cases, your

pleat line will not be a drastic slant, with a difference of less than

six inches between the top and bottom.

|

Optional step: For lined

swags and/or those which need to be pleated very carefully, I would recommend

laying the scarf flat, pinning through all layers of both pleating lines

very securely and sewing a straight line along the pleating line. This serves

two purposes:

-- It creates a line

on the front and back of the fabric to follow when pleating, thereby ensuring

that all the pleats are perfectly aligned.

-- It helps to secure

the lining in the tails and helps to prevent the lining/contrast from

rolling forward toward the front.

To mark the pleats,

measure the pleating lines. Most swags work best with 6 - 7 inches in each

pleat. Divide the pleating lines by 6 and/or 7. The answer will be the number

of pleats in your finished swag. Choose the one which most closely fits

your pleating line. Starting from the bottom of the each pleating line,

divide the line into 3 - 3.5" spaces. Make slight adjustments to each

pleat to accomodate the actual measure. You can have up to 1/2" more

in the bottom fold and 1/2" less in the top fold than the others if

necessary. Both pleating lines should be marked exactly the same. You must

have an even number of spaces on each pleating line.

Start with the bottom

and fold the first pleat towards the back. Accordian fold the pleats, following

your marks and aligning the stitching lines on top and back of fabric. The

top fold should fold towards the back. Turn the stack over and use an appropriate

sized safety pin to pin the back of the folds together. Do no catch the

top fold in this pin. It should be allowed to float free. Do the same with

the other pleating line.

|

|

| In

this treatment, I marked the top and bottom edges with t-pins and the

pleats with straight pins. I pleat along the slant edge. Once done, the

t-pins lined up perfectly at the back of the treatment. The straight pins

- which cannot be seen - lined up perfectly on the front of the folds. |

After pleating,

I used a safety pin to catch the folds of the pleats at the back of

the treatment. The bottom fold is shown here at the top. The top fold

is not caught in the safety pin.

|

Lay the scarf over the

holdbacks. The safety pins should lay to the back of the treatment on top

of the holdbacks, but can be pushed up to an inch to the left or right to

increase or decrease the center drop length. The swag should fall into shape

immediately with only minimal dressing. The tails will also fall into shape

easily. The tails will probably have one less fold than the swag. That fold

will disappear as you are dressing them. Do not fight the folds on the tails,

but let them dictate how they will fall.

CONCLUSION:

Once you have studied

and understand the components of the scarf swag, you will be able to design

and fabricate scarf swags with ease. Take for example the two following pictures

|

|

These are four separate

throw swags. They were ready-made scarves the client had purchased but was

unable to hang herself. She had mounted the two rods. In just a little over

two hours I met the new client, unloaded my tools and ladder, examined the

scarves and windows for the first time (the windows were different sizes

between the two rooms), measured, pleated and hung the scarves with the

same drop lengths - taking pictures at different steps along the way, packed

up my supplies, and collected payment.

The scarves were hung

so that the swag was pleated in the center for full panels on both sides.

They are laid over a pole instead of through holdbacks. Double-sided sticky

tape helps to stablize the edges on the poles. Otherwise they would slip

around. Also, the placement of the brackets at the corner of the window

and center of the window helped to stabilize the treatments. Safety pins

secured the treatment to the bracket.

The burgundy scarves

came to just floor length. Because the windows in the other room were narrower,

the scarves puddled on the floor. The client later tied them up as bishop

sleeves. The pleats in the scarves are secured with safety pins. Because

these are draped over a pole and over each other, rehanging them after cleaning

will present a small challenge. However, as long as the safety pins are

left in the pleats, the scarves will retain their swag shape.

You have mastered the

basic scarf swag. But now the design calls for more than one swag, asymmetrical

tails or some other variation. Scarf

Swags - Options & Variables will show you how to adapt the basic design

to many different variations.

A FINAL

WORD:

This article was written

to assist you in marking and pleating a scarf swag for a smooth installation.

For more detailed information

on how to manipulate a scarf swag, consider ordering The

Professional Workroom Handbook of Swags, Volume 1. The chapter on scarf

swags gives more detail than is contained in this article. It contains information

on mounting options as well as pictures and diagrams to aid your understanding.

This book is a valuable resource for new and veteran workrooms alike. It takes

the guesswork out of scarfswags.

Return to the Sew Easy Windows articles Table of Contents page.

|

![]()