| The

Basic Swag Pattern

Swags

come in many different shapes and sizes. Yet the basic shape of the pattern

and the method of pleating varies little between swags.

This

article takes you step by step through the process of making a simple

swag pattern, 40 inches wide by 18 inches long. It includes diagrams and

pictures. It is important to learn the basic swag shape and how it is

pleated. For the purpose of this article, I use standard defaults for

designing a swag pattern.

Symbol Guide

For computations,

this article uses the following math symbols:

|

+ |

Add |

|

| |

- |

Subtract |

|

| |

x |

Multiply |

|

| |

/ |

Divide |

|

| |

= |

Equals |

|

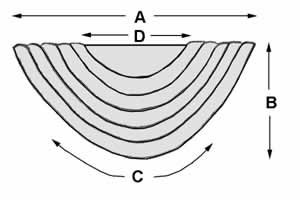

Identifying

the different parts of a finished swag:

The

center of a finished swag is the 'picture.' It showcases a motif on the

fabric. The first fold on the swag acts as the picture frame. The frame

can be adjusted to maximize the picture in the swag.

The

sides of the swag pattern are pleated into folds which are secured to

the top of the board or pole. The pleats each form a fold on the front

of the swag. Optimally, the folds should be equally spaced down the front

of the swag. Always check the folds on the back of the swag - they should

also be equally spaced to present a quality product from the street side

of the window. |

Drawing

the swag pattern:

|

Finished

Dimensions:

You must know the

dimensions of the finished swag before attempting to draw the pattern.

A = Finished width

is the full width of the swag when mounted at the board or pole line.

B = Finished length

is the longest point of the swag, measured from the center of the board

or pole line to the bottom of the swag.

|

|

C = Bottom curve

length is the catenary curve of the swag from the board line, down to

the longest point and up to the board line. To obtain this measure:

Drape a length

of weight chain from one end of the finished treatment to the other.

Hold the chain on top of the board at each end at the point where

the fabric will end. This will give you a finished curve length which

includes the board allowance. Measure the length of the weight chain

and that will be your bottom curve length.

D = Top width of

the swag picture. This is also the top width of the swag pattern.

For our sample swag,

the finished width will be 40", the finished length will be 18"

and the bottom curve length will be 60".

|

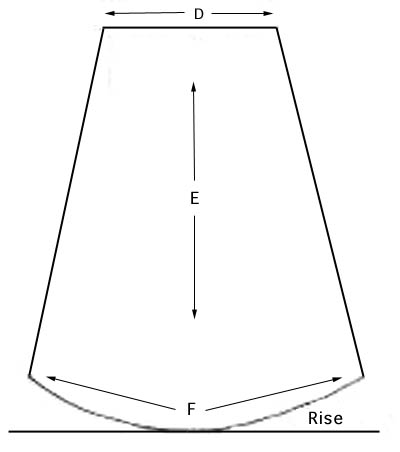

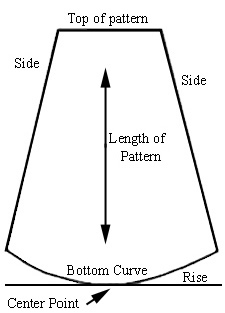

D

= Width of top of pattern. For most swags, you will draw the pattern

width at 1/2 the finished width.

Our sample swag is 40" wide finished, therefore the pattern will

be drawn with a 20" wide top width.

E

= Length of pattern. For most swags, you will draw the pattern length

at two times the finished drop length. Always add 4" to your length.

Our finished sample swag wil be 18" long. Therefore, the pattern

must be drawn 40" long {(18 x 2) + 4}.

C

= Bottom curve length of pattern. Our sample swag of 40" wide by

18" long will have a curve length of 60".

Rise

= The distance the curve line rises above the bottom edge of the pattern.

Swags which are 1/2 circles (length is 1/2 width), the rise is 1/2 the

finished length.

For

our sample swag, the rise will be 9". |

|

|

|

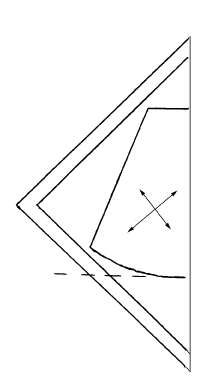

Cutting

the Pattern:

Fold

the lining diagonally as shown. Measure out 1/2 of the pattern from the

fold line of the fabric.

Mark

the straight of grain.

Cut

|

|

|

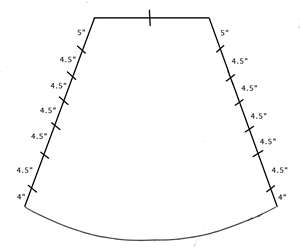

Marking

the Pattern:

Open

flat and mark the center of the top edge.

Mark

the pleats as follows:

- 5"

from the top for first pleat. This will determine your picture size.

- 4"

up from the bottom.

- Divide

the space between the first and last pleat into equal pleats of 4-6".

All

of the pleats between the first and last must be equal in size.

|

|

|

Pleating

The Swag Pattern:

Use

a covered board, preferably the one on which it will be mounted. Mark

the center of the board. |

|

Pin

the top edge of the pattern 2" up on the top of the board, aligning

the center marks.

Pleat

the first fold, right side and left side. Align point of the pleat along

the edge of the top of the pattern.

This

first fold sets the 'picture' on your swag. |

|

|

Continue

pleating all but the last fold.

The

distances between the pleats and the angle at which they fall off the

board should be equal for all pleats. Pleat the left side exactly the

same as the right. |

|

|

Pleat

the last fold. You will also have to take the end of it and pull it up

onto the board to secure. This will cause the bottom edge of the swag

to tuck neatly up. This last pleat can be wider than the finished width

by 1/2" on each side. This is your seam allowance for the finished

swag. |

|

This article gives

you only the bare bones of drawing a swag pattern for a board mounted swag.

The dimensions it gives are for a very specific size of swag. The swag pattern

is a marvel of engineering whereby the flat cut of the pattern can be transformed

into a three-dimensional curved swag.

|

The top of pattern

sets the picture area width and general shape of the swag.

The length of the

pattern and the pleated sides combine to give the swag its character.

The length of the pattern determines the fullness of the swag. The sides

are pleated into folds which distribute the fullness and give the swag

visual interest.

The bottom curve,

center point and rise combine to define the shape of the lower edge of

the swag and the distribution of the folds. |

|

This article also only touched

on the board mounted swag. The Cutout Swag (aka Pole Swag) and Point-to-Point

(aka Drapery) Swags are variations of the basic board mount swag. These three

styles of swags are the basic building blocks for all other swags - Arched,

Turban, Kingstons, Empires, Turban, Boxed, Swagged panels and so on. Once you

have mastered these three and understand the relationship of pattern components

to the finished swag, you will be able to adjust and troubleshoot most any swagged

treatment with more ease.

If you wish to learn more

about the engineering properties of the swag pattern, consider ordering the

book "The Professional

Workroom Handbook of Swags, Volume 1."

Return to the Sew Easy Windows articles Table of Contents page.

|

![]()